mould technology

Mold inspection tools

and automotive fixtures

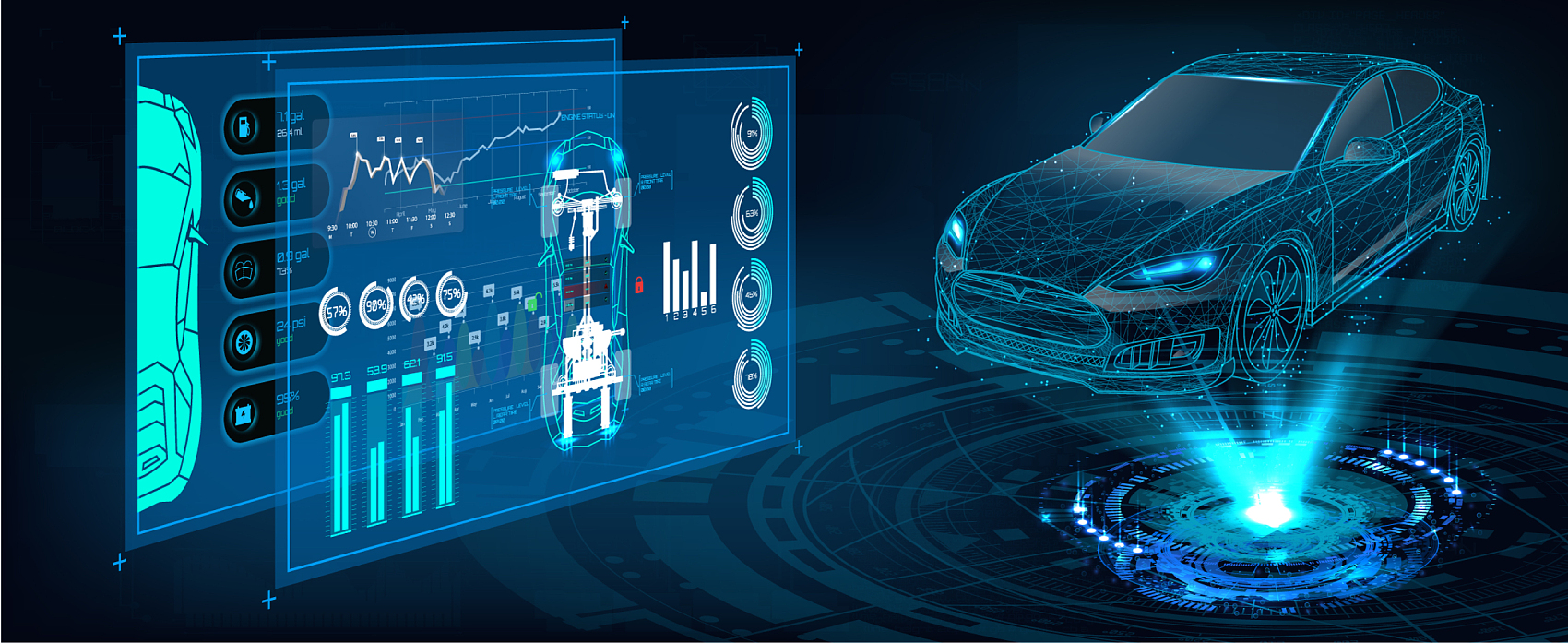

automotive technology

Huda Sanjia has the ability of mold design and

manufacturing, CAE analysis of stamping forming,

synchronous engineering of body development, CAM

processing of complex mechanical products, and

processing of foam production of product samples. It has

formed unique technical advantages in mold aspects such

as roof outer plate, fender, B-pillar stiffener, etc. It is one of

the few automobile mold manufacturers in China and is

deeply trusted and supported by its partners.

Sheet metal parts inspection tools play a decisive role in

the quality control of parts. Huda Sanjia integrates design

and development, production and manufacturing, and

after-sales service, prioritizing service and quality to

meet the needs of customers in the automotive

inspection tool industry. Adhering to the "craftsman spirit"

for 20 years, it has focused on customizing high-end

automotive inspection tool components.

The company has excellent integration and development

capabilities for new energy vehicle (whole vehicle) systems,

including overall vehicle layout design and performance

target setting, system architecture design, development

and modeling, and CAE analysis. The EC35 pure electric

logistics vehicle developed for Chongqing Ruichi in 2015

was successfully launched in bulk that year and won the

"2015 Pure Electric Logistics Vehicle Award" at the 6th

Global New Energy Vehicle Conference in January 2016. It

has won the monthly sales championship of pure electric

logistics vehicles multiple times and has now accumulated

nearly 100000 units; The lightweight project of pure electric

passenger vehicles of Changan Automobile Science and

Technology Department successfully passed the acceptance

organized by the Ministry of Science and Technology of the

People's Republic of China in 2022. The aluminum body

framework of large cars has achieved mass production,

stable quality, controllable cost, lightweight forged

aluminum steering knuckles, swing arms and small batch

trial assembly, and passed the test.

Every year, we update and upgrade the UG3D

database and selection manual, striving to facilitate

the design of automotive inspection tools and

reduce their manufacturing costs. At the same time,

in the field of automotive welding fixtures, we

always pay attention to cutting-edge directions,

update and learn advanced technologies, and

continuously enrich and innovate while undertaking

projects. With rich practical production experience,

we have formed our own unique technical

advantages.

For example, since its establishment, under the guidance

of two academician teams, the company has been

engaged in research on rebound technology challenges,

conducted a large number of material forming rebound

experiments, accumulated rich experience, and applied

CAE high-precision simulation calculations to accurately

calculate rebound; The Reverse engineering technology is

applied to establish the mold, and the simulation error

compensation model is used to realize the precise control

of part springback.